ArtisticGraver, ArtistGraver and ArtGraver Machines and Handpieces

Lindsay Engraving & Tools - When quality means everything. In Your work and Ours!

Family Owned!

46 Year

History Tools Designed and Made in USA!

Follow on

Instatgram

Patented Lindsay Uniform Parallel point™ Geometry

|

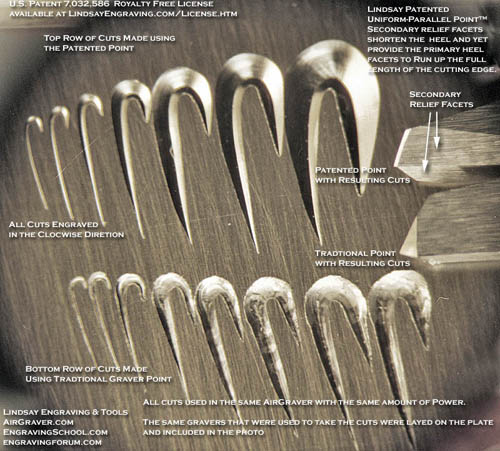

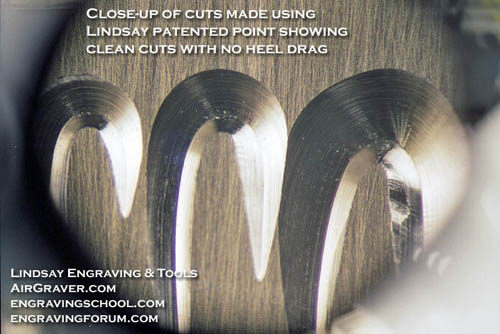

The Patented Lindsay Uniform Parallel point™ is a V shaped graver point with relieved heels that works with any width V graver point, from a narrow V to a wide V. The most noticeable feature of the geometry is parallel heels with two long secondary relief facets on the bottom of the point. U.S. Patent # 7,032,586

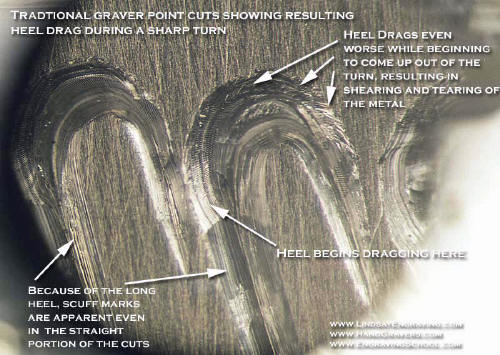

Benefits of the Patented Point Geometry The photo above is an overall shot of the plate. The two gravers that were used are lying on the plate rotated so that the heels of the gravers are visible. The upper row of cuts were made using the uniform point, and the lower row were made with a traditional point. The two photos below are close-ups of the above plate traditional point cuts. Click photos to enlarge The two photos below are close-ups of the above plate uniform point cuts. Click photos for more detail |

|

The Uniform Parallel point™ is similar to having two flat graver points joined together to form a V. While engraving, lean it to one side or the other and it will cut wide like a flat point. This makes the point versatile and allows a person to vary the width of the cut from thin to thick easily. The engraving to the right would have been difficult if not impossible to execute well without this point. Being able to vary the width of the cut using one point to create fine banknote lines and wide lines gives the artist the ability to express himself easily. One pre-sharpened Carbalt™ graver with this point is included with each Lindsay handpiece. The Lindsay sharpening system easily and accurately grinds the patented point. |

|

|

Additional

benefits The uniform parallel

geometry has a shorter heel because of the secondary relief facets, and

allows the cutting edge to go through the metal cleanly. The point more

efficient in cutting, and required less power than a traditional point to

execute a cut of the same depth. The cuts in the sample plate illustrate

this by the dramatic increased depth seen in the cuts made by the patented

geometry, given the same amount of power and impact frequency as the

traditional point cuts. Since the point is cutting more easily, there is

less force on it, and therefore the breaking of points is less likely. |

|

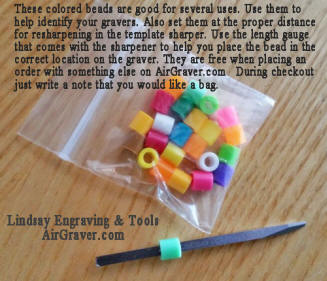

Lindsay Graver Sharpener System Simple, Quick and most of all repeatable dead-on accurate to reproduce the patented Uniform Parallel Point™ The system uses

inexpensive templates to reproduce various points easily and accurately. |

Links to the graver

sharpening information:

Sharpener instruction page

Tim Wells video of the process with a power hone.

Sharpener length gauge distances

Chris Botha video with the onglette template

Using a drill press for sharpening hone

.png)

_small.png)